Made in Norway

SBX has been designed, engineered, and is still manufactured in our home country of Norway.

The context of Safeback's product as a new technology that can increase the margins of survival has led us to think differently about the standards we keep for producing it.

After much consideration, we determined that the best way to secure the quality and reliability of our product, as well as allow us to be nimble in future iterations was to produce the product in our home country: Norway.

Our Design Challenges

Core Function: Supplying Air through snow

Sourcing the "right" materials

Balancing User needs and engineering constraints

Quality Control

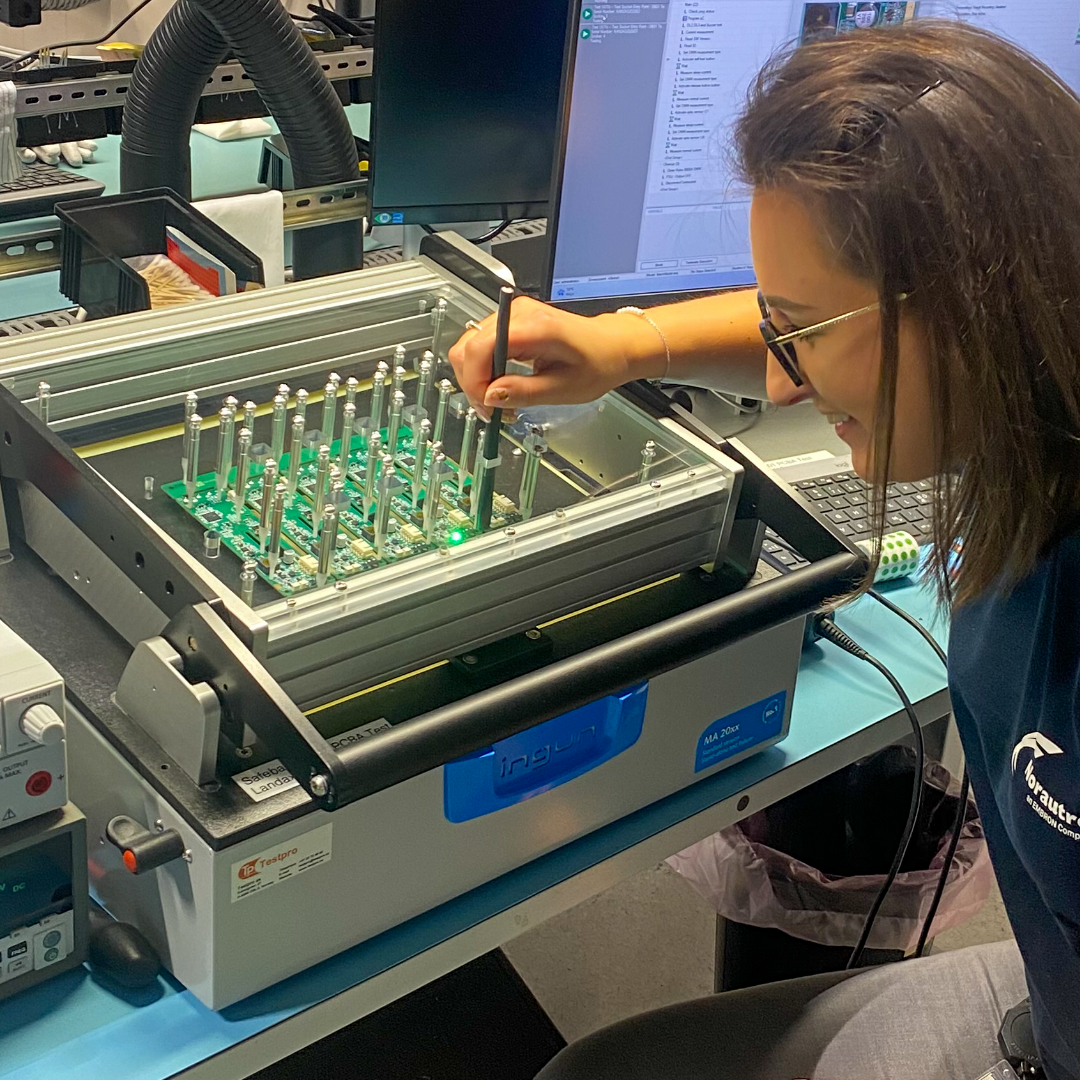

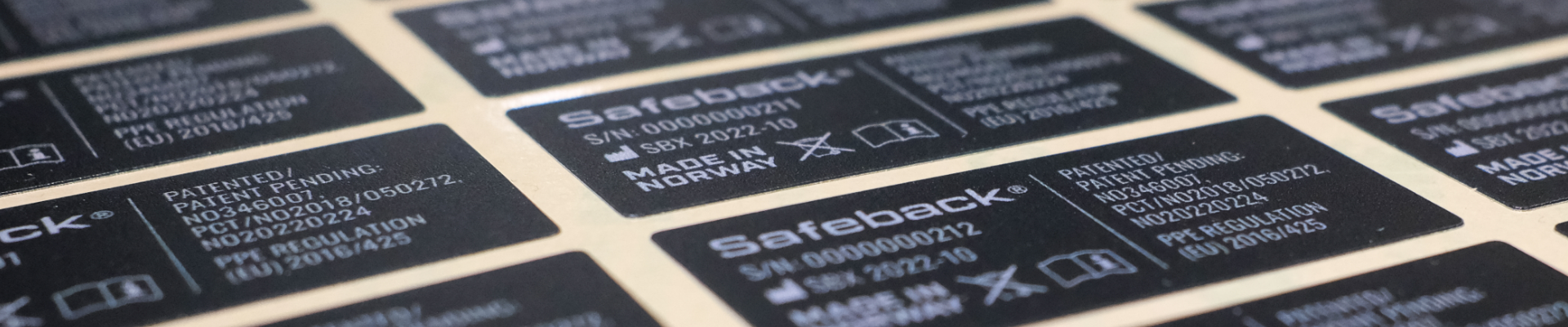

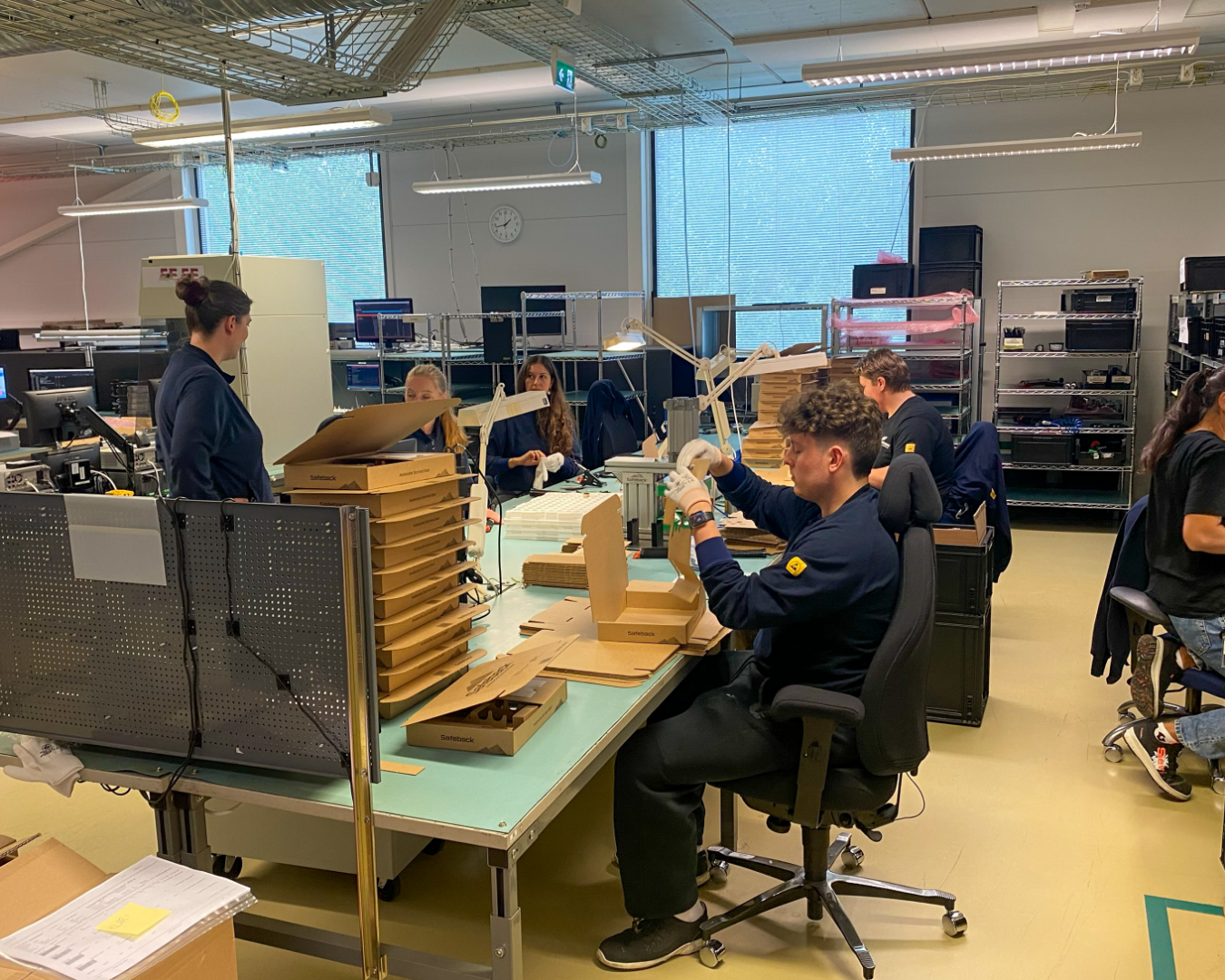

Meet our factory: Norautron

We produce SBX at a high-end electronic manufacturer in Norway called Norautron. They are responsible for electronics manufacturing, and final assembly of the system, including QA. Their production of PCBs is fully automated and traceable, including a functionality test on all units before they are sent for installation. Post-assembly testing includes a final QA test for unit functionality on all units, meaning no SBX units leave the factory until they are confirmed as fully functional. In addition, we are proud to support a factory with the highest labor standards, that provides a healthy workplace for their employees, and has achieved several international standards for their efforts.

Manufacturing close to home

Throughout development, we grew to see the advantages of production in Norway. We have greater control over the quality of every component and how they are assembled, ensuring the highest standards are maintained for what is a worst-case safety product.

Collaborating with local manufacturers and suppliers ensured top-notch quality and facilitated effective communication and streamlined logistics. Being able to visit the manufacturing facility regularly allowed us to closely monitor the production process, make necessary adjustments, and maintain a close relationship with our manufacturing partners.

The decision to manufacture in Norway was driven by our commitment to excellence and the desire to provide our customers with a product they can rely on in the most demanding situations. We incorporated materials resistant to impact, and the design elegantly integrates the air inlet for the fan, into the product's aesthetic.

Testing from Product Development

Snow Burial Simulations

To confirm the findings of our modeled research, we created burial simulations to test iterations of our system and measure the actual airflow it generated in the snow.

Read more

Technical Solutions for Supplying Air Through Snow

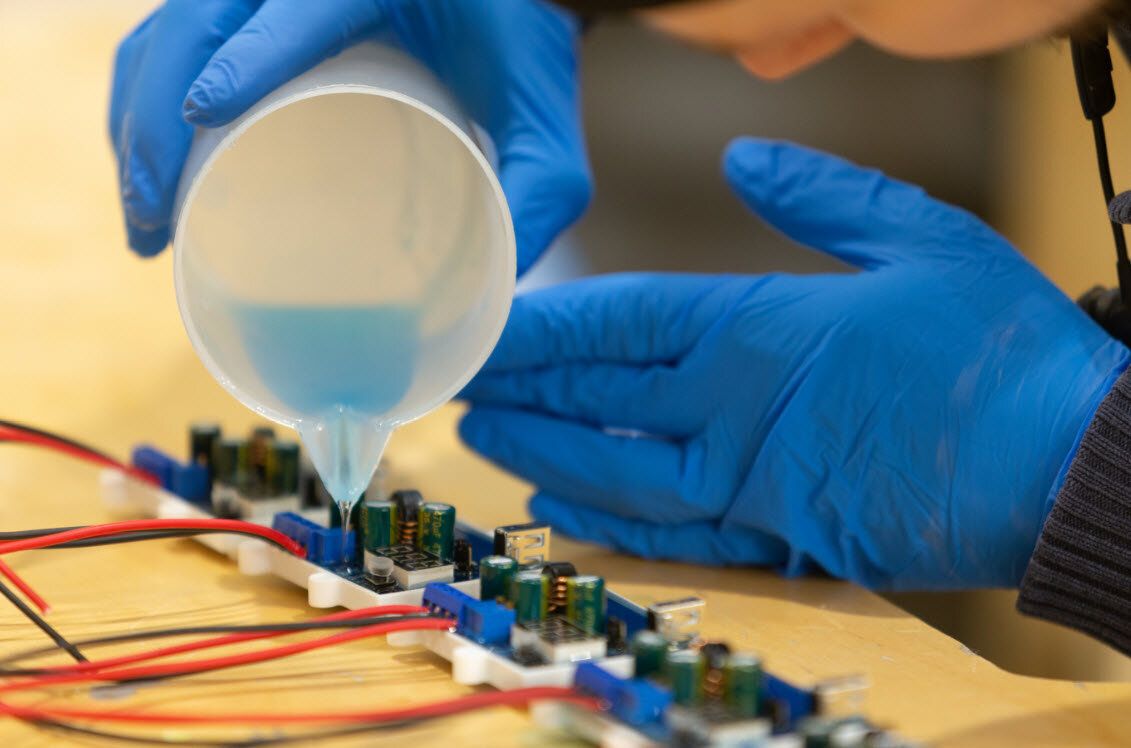

Developing the Safeback SBX system has required significant testing of all components, both individually and as an integrated system.

Read more

Practical Field Testing

The system has been developed to withstand harsh conditions and tough use, in temperatures down to -30 degrees - requiring rigorous testing of all components individually, and as a system.

Read moreBackpacks with Safeback SBX

Safeback SBX

Designed to provide breathable air to an avalanche victim under the snow, extending their potential survival window.